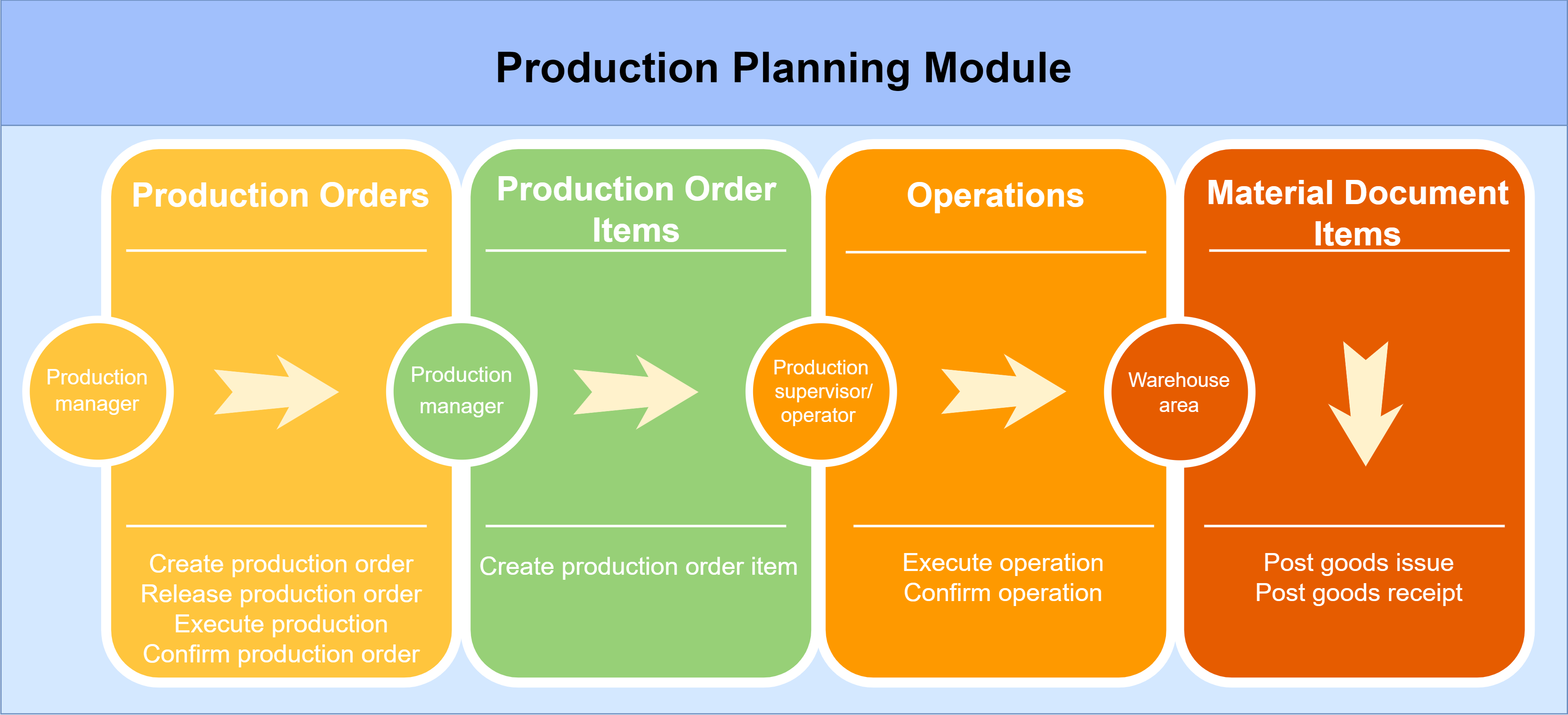

This app template was built for the SAP ECC Production Planning process. This is an end-to-end process that usually starts with the creation of a production order. Then, the production order is released and its operations are executed. After that, the production confirmation is created and the material movements (Post goods issue for material consumption and Post goods receipt of the finished product) are done. Finally, the production order is moved to 'Technically completed' status and the process ends.

This process includes the following types of Production orders:

The graphic below briefly shows a standard SAP ECC Production Planning process:

The following tags are available by default.

| Tag | Description |

|---|---|

| Long-lasting open order | Cases that are actively in 'Released' status for more than the regular time that it should take for that material and plant to process it. That regular time is calculated based on the sum of average time and standard deviation of the release-to-finish throughput time for each combination of material and plant. Orders that are still opened could keep the hold on the raw materials needed for them, besides having other unwanted effects on the overall process. Therefore, it's a good idea to understand why they're still opened and suggest their closure if possible. |

| Multiple Release statuses | Having the 'Release' status repeated multiple times means that there was some sort of reversal of the following statuses and the order went back to 'Released'. This is clearly a rework done to the order and it should be avoided. |

| Multiple Technically completed statuses | Having the 'Technically completed' status repeated multiple times means that there was some sort of reversal of the following statuses and the order went back to 'Technically completed'. This is clearly a rework done to the order and it should be avoided. |

| Order with change activities | Cases that have their attributes changed. Changes to orders are generally frown upon and they are a good indicator of inefficiencies or activities that do not add any value. |

| Order with rework required | Cases where production rework is required. This tag applies only to the original orders that were reworked (i.e. Re-work orders are filtered out). All rework activities show inefficiencies in the production process. |

| Production quantity deficit | Cases where the production order generated less quantity than expected which can be understood as a lack of efficacy. It is worth the effort to understand why this is happening in those cases. |

| Scrap portion exceeded | Cases which exceeded the portion of scrap estimated for that order. Creating more scrap than estimated means that the consumption of materials during the production process is greater than the standard. It's important to understand their root causes so they can be avoided. |

| Total order quantity changed after release | All changes in quantities done after the release of an order would render all calculations done by the system (e.g. raw materials availability) incorrect. Therefore, these changes could potentially impact the production process as they are bypassing the validations done by SAP during the release of the order. |

| Zero-quantity confirmations | Confirmations done with zero quantity entered do not usually make sense. Therefore, it requires attention to validate that these activities were correctly done or they are actually showing inefficiencies in the process. |

The following due dates are available by default.

| Due date | Description |

|---|---|

| Basic finish date | Compares the date the user defines as the finished date for the production order (basic finish date) with the date it actually finished. |

| Basic start date | Compares the date the user defines as the start date for the production order (basic start date) with the date it actually started. |

| Scheduled finished date | This due date compares the date when the system estimates the production order should finish (scheduled finish date, based on predefined production parameters) with the date it actually ended. |

| Scheduled release date | This due date compares the date when the system estimates the production order should be released (scheduled release date, based on predefined production parameters) with the date it actually got released. |

| Scheduled start date | This due date compares the date when the system estimates the production order should start (scheduled start date, based on predefined production parameters) with the date it actually started. |

The SAP ECC Production Planning (PP) module is mandatory.

This app template contains models based on historical information. This information is contained in the following tables:

The tracking of these changes in SAP ECC PP must be configured.

Detailed instructions can be found in the section Instructions for enabling History Tracking in SAP ECC Production Planning.

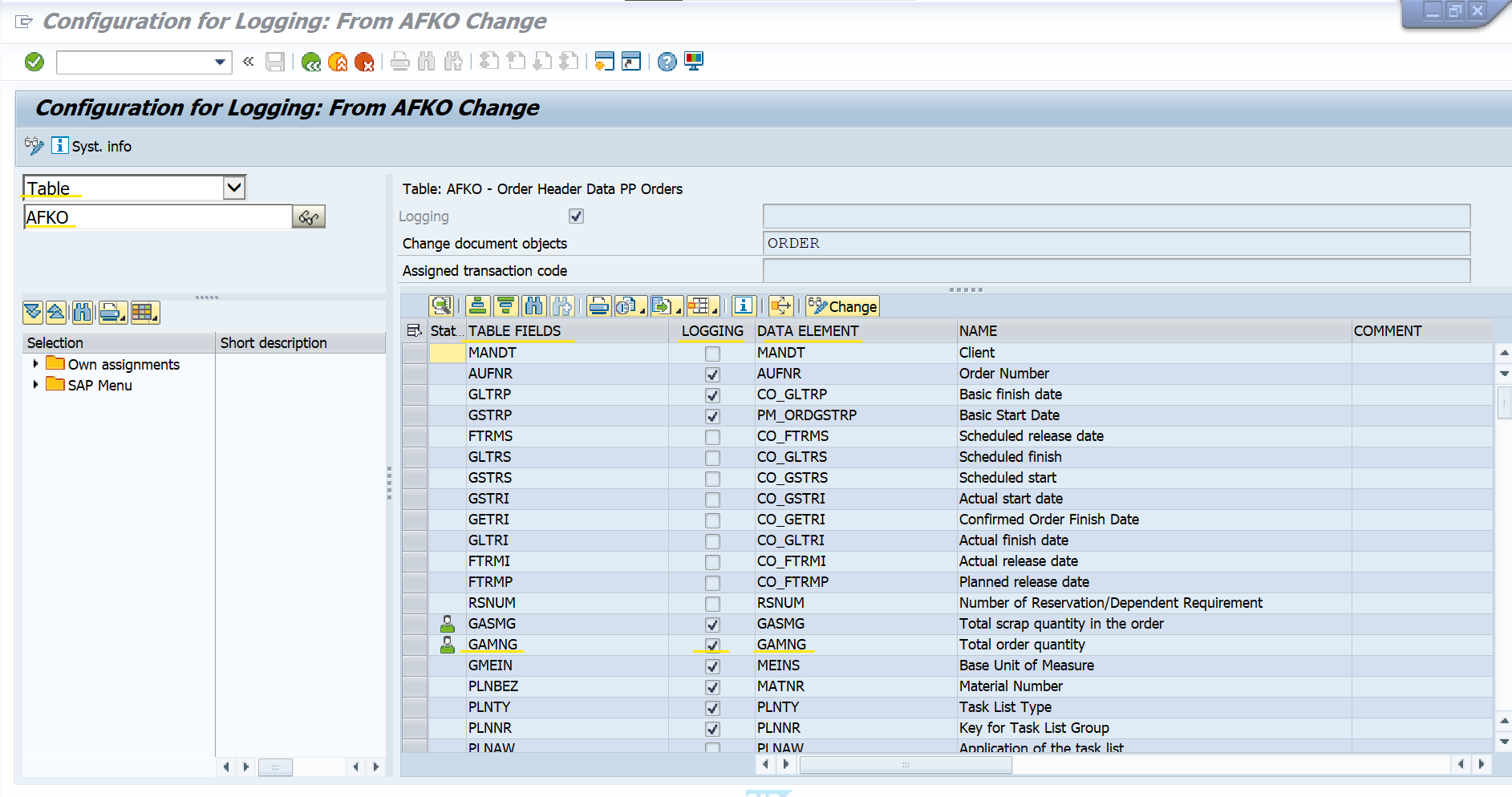

For this app template, the specific fields which need to be enabled in SAP are the following:

CDPOS tracking

| Table | Fields |

|---|---|

| AUFK | KTEXT |

| AFKO | GAMNG, TERKZ, GLTRP, GSTRP, GLUZP, GSUZP, GASMG, APRIO |

| AFPO | PSMNG, PSAMG, LGORT, DNREL, INSMK |

| AFVC | LTXA1 |

JCDS tracking of status

Select all desired types of Production orders.

The data extraction is developed for SAP and is using Theobald Xtract Universal. In general, you should follow the steps as described in Loading Data Using Theobald Xtract Universal (Automation Cloud) to set up data loading using Theobald Xtract Universal. Note: If you are using Automation Suite, make sure to select AUTOMATION SUITE as the DELIVERY option on the documentation page. In addition, select the Automation Suite version you are using to open the appropriate Loading Data Using Theobald Xtract Universal page.

destinations, extractions, and sources. Copy the folders from the downloaded zip file to the config folder of Xtract Universal. The location of this folder is [XU_installation_path]/config.extract_theobald.ps1 script and the config.json file. Unzip the content on the server where Theobald Xtract Universal is installed.The following table provides an overview of the different field types and their default format settings.

| Field type | Description |

|---|---|

| boolean | true, false, 1, 0 |

| date | yyyy-mm-dd |

| datetime | yyyy-mm-dd hh:mm:ss[.ms], where [.ms] is optional |

| double | Decimal separator: . (dot); thousand separator: none |

| integer | Thousand separator: none |

| text | N/A |

| Transactional Data | Master Data |

|---|---|

| AFKO | ADCP |

| AFPO | ADRP |

| AFRU | MARC |

| AFVC | MARM |

| AUFK | MBEW |

| CDHDR | T001L |

| CDPOS | T001W |

| JCDS | T001 |

| JEST | T003P |

| MSEG | T006A |

| T156T | |

| T156 | |

| TCA02 | |

| TCURF | |

| TCURR | |

| TCURX | |

| TGSBT | |

| TJ02T | |

| TKA01 | |

| TTZCU | |

| TTZDF | |

| TTZDV | |

| TTZD | |

| TTZR | |

| TTZZ | |

| USR02 | |

| USR21 |

Header input table for Order data.

| Field | Type | Description |

|---|---|---|

MANDT |

text | Client Identifier (Primary Key). |

AUFNR |

text | Production order number (Primary Key). |

GASMG |

double | Expected scrap quantity |

GETRI |

date | Indicates the actual finish date for the order. |

GEUZI |

time | Indicates the actual finish time for the order. |

FTRMI |

date | Indicates the actual release date for the order. |

GSTRP |

date | Indicates the basic start date for the order. |

GSUZP |

time | Indicates the basic start time for the order. |

GLTRP |

date | Indicates the basic finish date for the order. |

GLUZP |

time | Indicates the basic finish time for the order. |

AUFPL |

text | Routing number of operations in the order. |

GSTRS |

date | Indicates the scheduled start date for the order. |

GSUZS |

time | Indicates the scheduled start time for the order. |

GLTRS |

date | Indicates the scheduled finish date for the order. |

GLUZS |

time | Indicates the scheduled finish time for the order. |

FTRMS |

date | Indicates the scheduled release date for the order. |

IASMG |

double | Confirmed scrap quantity |

RMNGA |

integer | Indicates the number of confirmed rework quantity in the order. |

Filtering: This table doesn't have any date field that can be used for filtering purposes. Therefore, it was joined with AUFK table to bring the filter by date when loaded from source.

Item input table for Order data.

| Field | Type | Description |

|---|---|---|

MANDT |

text | Client Identifier (Primary Key). |

POSNR |

text | Production order item number (Primary Key). |

AUFNR |

text | Production order number (Primary Key). |

AMEIN |

text | Foreign key identifying the base unit of measure in-house. |

GSBER |

text | Foreign key identifying the business area. |

UMREN |

double | Denominator to convert into base unit of measure. |

WEMNG |

double | Indicates the goods received quantity. |

MATNR |

text | Foreign key identifying the material number. |

MEINS |

text | Foreign key identifying the base unit of measure. |

UMREZ |

double | Numerator to convert into base unit of measure. |

OBJNP |

text | Object number for the order item. |

DAUTY |

text | Foreign key identifying the order category. |

PSMNG |

double | Indicates the production order item quantity. |

DAUAT |

text | Foreign key identifying the order type. |

PLNUM |

text | Planned production order number. |

DWERK |

text | Foreign key identifying the order item's plant. |

PSAMG |

double | Indicates the production order item scrap quantity. |

LGORT |

text | Foreign key identifying the storage location. |

Filtering: This table doesn't have any date field that can be used for filtering purposes. Therefore, it was joined with AUFK table to bring the filter by date when loaded from source.

Input table for Order confirmations.

| Field | Type | Description |

|---|---|---|

MANDT |

text | Client Identifier (Primary Key). |

RUECK |

text | Completion confirmation number for the operation (Primary Key). |

RMZHL |

text | Confirmation counter for the operation (Primary Key). |

GMEIN |

text | Foreign key identifying the base unit of measure. |

STZHL |

integer | Cancelled confirmation indicator. |

LTXA1 |

text | Description for the confirmation. |

IEDD |

date | Confirmed date for the operation's execution finish. |

ISDD |

date | Confirmed date for the operation's execution start. |

ERSDA |

date | Confirmation entry date. |

ERZET |

time | Confirmation entry time. |

MEINH |

text | Foreign key identifying the unit of measure for the confirmation. |

IEDZ |

time | Confirmed time for the operation's execution finish. |

ISDZ |

time | Confirmed time for the operation's execution start. |

APLZL |

text | General counter for order. |

AUFNR |

text | Foreign key identifying the production order number. |

AUERU |

text | Partial-final confirmation indicator. |

GMNGA |

double | Indicates the quantity confirmed. |

STOKZ |

text | Reverse indicator. |

AUFPL |

text | Routing number of operations in the order. |

XMNGA |

double | Indicates the scrap confirmed. |

ERNAM |

text | Name of the person who created the record. |

Filtering: This table doesn't have any date field that can be used for filtering purposes. Therefore, it was joined with AUFK table to bring the filter by date when loaded from source.

Input table for Operations within an order.

| Field | Type | Description |

|---|---|---|

MANDT |

text | Client Identifier (Primary Key). |

APLZL |

text | General counter for order (Primary Key). |

AUFPL |

text | Routing number of operations in the order (Primary Key). |

OBJNR |

text | Object number for the operation. |

LTXA1 |

text | Indicates the operation name. |

PLNTY |

text | Foreign key identifying the operation type. |

Filtering: This table doesn't have any date field that can be used for filtering purposes. Therefore, it was joined with AFKO table to bring the filter by date when loaded from source.

Input table for Order data.

| Field | Type | Description |

|---|---|---|

MANDT |

text | Client Identifier (Primary Key). |

AUFNR |

text | Production order number (Primary Key). |

BUKRS |

text | Foreign key identifying the company code. |

KOKRS |

text | Foreign key identifying the controlling area. |

ERDAT |

date | Date on which the record was created. |

ERFZEIT |

time | Time on which the record was created. |

OBJNR |

text | Object number for the order. |

AUTYP |

text | Indicates the order category. |

AUART |

text | Indicates the order type. |

ERNAM |

text | Name of the person who created the record. |

Filtering: Date: ERDAT and AUTYP in ('10', '40').

Header input table for object changes.

| Field | Type | Description |

|---|---|---|

MANDANT |

text | Client Identifier (Primary Key). |

CHANGENR |

text | Change record identifier (Primary Key). |

OBJECTCLAS |

text | Object class category (Primary Key). |

OBJECTID |

text | Object value (Primary Key). |

UDATE |

date | Date the change was executed. |

UTIME |

time | Time the change was executed. |

USERNAME |

text | User who executed the change. |

Filtering: Date: UDATE.

Log table for field change events for Work Orders, Operations and Notifications.

| Field | Type | Description |

|---|---|---|

TABKEY |

text | Change table record identifier (Primary Key). |

CHNGIND |

text | Identifies the type of change made (insertion, update) (Primary Key). |

MANDANT |

text | Client Identifier (Primary Key). |

CHANGENR |

text | Change record identifier (Primary Key). |

FNAME |

text | Field which was updated (Primary Key). |

OBJECTCLAS |

text | Object class category (Primary Key). |

OBJECTID |

text | Object value (Primary Key). |

TABNAME |

text | Table name where the change was executed (Primary Key). |

VALUE_NEW |

text | Value which was updated into the table. |

VALUE_OLD |

text | Value which was updated out of the table. |

Filtering:

CDHDR table to bring the filter by date when loaded from source.FNAME != 'KEY', TABNAME in ('AUFK', 'AFKO', 'AFPO', 'AFVC', 'AFRU').Input table containing all status changes for Production orders.

| Field | Type | Description |

|---|---|---|

CHGNR |

text | Change record identifier (Primary Key). |

MANDT |

text | Client Identifier (Primary Key). |

OBJNR |

text | Object number (Primary Key). |

STAT |

text | Status to which the object was updated (Primary Key). |

UDATE |

date | Date when the change was executed. |

UTIME |

time | Time when the change was executed. |

USNAM |

text | Name of the person who executed the change. |

INACT |

text | Indicates if the status is active. |

Filtering: Date: UDATE and INACT = '' or is null.

Table that keeps track of all current statuses for an order.

| Field | Type | Description |

|---|---|---|

MANDT |

text | Client Identifier (Primary Key). |

OBJNR |

text | Object number (Primary Key). |

STAT |

text | Active status of the object (Primary Key). |

INACT |

text | Indicates if the status is active. |

Filtering:

AUFK table to bring the filter by date when loaded from source.INACT = '' or is null.Input table for Material Document Items.

| Field | Type | Description |

|---|---|---|

MANDT |

text | Client Identifier (Primary Key). |

ZEILE |

text | Material document item number (Primary Key). |

MBLNR |

text | Material document item (Primary Key). |

MJAHR |

text | Material Document Year Identifier (Primary Key). |

CPUDT_MKPF |

date | Date the accounting document was entered. |

CPUTM_MKPF |

time | Time the accounting document was entered. |

KZVBR |

text | Indicates the consumption posting. |

MATNR |

text | Foreign key identifying the material number. |

KZBEW |

text | Movement indicator. |

BWART |

text | Foreign key identifying the movement type. |

AUFPS |

text | Indicates the order item number. |

AUFNR |

text | Indicates the order number. |

KZZUG |

text | Receipt indicator. |

SOBKZ |

text | Special stock indicator. |

USNAM_MKPF |

text | Indicates the user name. |

Filtering: Date: CPUDT_MKPF and AUFNR != ''.

Input table for Person/Address Assignment (Business Address Services) data.

| Field | Type | Description |

|---|---|---|

ADDRNUMBER |

text | Address Number of the Business (Primary Key). |

CLIENT |

text | Client Identifier (Primary Key). |

DATE_FROM |

date | Date from which record applies (Primary Key). |

NATION |

text | Identifier for international addresses. |

PERSNUMBER |

text | Identifier of the person/user (Primary Key). |

DATE_TO |

date | Date to which record applies. |

DEPARTMENT |

text | Department the user is assigned to. |

FUNCTION |

text | Function or role of the user. |

Filtering: NATION = '' or NATION = 'I'.

Input table for Persons (Business Address Services) data.

| Field | Type | Description |

|---|---|---|

CLIENT |

text | Client Identifier (Primary Key). |

DATE_FROM |

date | Date from which record applies (Primary Key). |

NATION |

text | Identifier for International Addresses (Primary Key). |

PERSNUMBER |

text | Identifier of the person/user (Primary Key). |

DATE_TO |

date | Date to which record applies. |

NAME_FIRST |

text | Name of the User. |

NAME_LAST |

text | Last name of the User. |

Filtering: NATION = '' or NATION = 'I'.

Input table for Plant data for Material data.

| Field | Type | Description |

|---|---|---|

MANDT |

text | Client Identifier (Primary Key). |

MATNR |

text | Material Number Identifier (Primary Key). |

WERKS |

text | Plant (Primary Key). |

KZKUP |

text | Indicator: Material can be co-product. |

Input table for Units of Measure for Material data.

| Field | Type | Description |

|---|---|---|

MANDT |

text | Client Identifier (Primary Key). |

MATNR |

text | Material Number Identifier (Primary Key). |

MEINH |

text | Alternative Unit of Measure for Stock keeping Unit (Primary Key). |

UMREN |

double | Denominator for conversion to base units of measure. |

UMREZ |

double | Numerator for Conversion to Base Units of Measure. |

Input table for Material Valuation data.

| Field | Type | Description |

|---|---|---|

MANDT |

text | Client Identifier (Primary Key). |

MATNR |

text | Material Number Identifier (Primary Key). |

BWKEY |

text | Valuation Area (Primary Key). |

BWTAR |

text | Valuation Type (Primary Key). |

VERPR |

double | Moving average price/Periodic unit price. |

PEINH |

double | Unit price. |

STPRS |

double | Standard price. |

Input table for Company Codes data.

| Field | Type | Description |

|---|---|---|

MANDT |

text | Client Identifier (Primary Key). |

BUKRS |

text | Company Code (Primary Key). |

BUTXT |

text | Identifies the company name. |

WAERS |

text | Foreign key identifying the currency key. |

Input table for Storage Locations data.

| Field | Type | Description |

|---|---|---|

MANDT |

text | Client Identifier (Primary Key). |

WERKS |

text | Plant (Primary Key). |

LGORT |

text | Storage Location (Primary Key). |

LGOBE |

text | Description of storage location. |

Input table for Plants/Branches data.

| Field | Type | Description |

|---|---|---|

MANDT |

text | Client Identifier (Primary Key). |

WERKS |

text | Plant Code identifier (Primary Key). |

NAME1 |

text | Plant name. |

BWKEY |

text | Valuation Area. |

Input table for Order Type Descriptions data.

| Field | Type | Description |

|---|---|---|

CLIENT |

text | Client Identifier (Primary Key). |

SPRAS |

text | Language Key (Primary Key). |

AUART |

text | Order Type (Primary Key). |

TXT |

text | Order Type description. |

Filtering: SPRAS = var("language").

Input table for Measurement unit data.

| Field | Type | Description |

|---|---|---|

MANDT |

text | Client Identifier (Primary Key). |

SPRAS |

text | Language key identifier (Primary Key). |

MSEHI |

text | Measurement unit (Primary Key). |

MSEHT |

text | Measurement unit description. |

Filtering: SPRAS = var("language").

Input table for Movement Type data.

| Field | Type | Description |

|---|---|---|

MANDT |

text | Client Identifier (Primary Key). |

BWART |

text | Movement Type Identifier (Primary Key). |

SHKZG |

text | Debit/Credit indicator. |

XSTBW |

text | Reversal movement type. |

Input table for Movement Type descriptions data.

| Field | Type | Description |

|---|---|---|

MANDT |

text | Client Identifier (Primary Key). |

KZVBR |

text | Consumption Posting (Primary Key). |

SPRAS |

text | Language key identifier (Primary Key). |

KZBEW |

text | Movement indicator (Primary Key). |

BWART |

text | Movement Type Identifier (Primary Key). |

KZZUG |

text | Receipt indicator (Primary Key). |

SOBKZ |

text | Special stock indicator (Primary Key). |

BTEXT |

text | Movement Type description. |

Filtering: SPRAS = var("language").

Input table for Language-dependent texts for TCA01: Task list types data.

| Field | Type | Description |

|---|---|---|

MANDT |

text | Client Identifier (Primary Key). |

SPRAS |

text | Language key identifier (Primary Key). |

PLNTY |

text | Task List Type (Primary Key). |

TXT |

text | Description of the task list type. |

Filtering: SPRAS = var("language").

Input table for Conversion Factors data.

| Field | Type | Description |

|---|---|---|

MANDT |

text | Client Identifier (Primary Key). |

KURST |

text | Exchange rate type used for the conversion (Primary Key). |

FCURR |

text | Original currency (Primary Key). |

GDATU |

date | Date in which the record was created (Primary Key). |

TCURR |

text | Destination currency of the exchange rate (Primary Key). |

FFACT |

double | Ratio for the "From" Currency Units. |

TFACT |

double | Ratio for the "To" Currency Units. |

Filtering: KURST = var("exchange_rate_type").

Input table for Exchange Rates data.

| Field | Type | Description |

|---|---|---|

MANDT |

text | Client Identifier (Primary Key). |

KURST |

text | Exchange rate type used for the conversion (Primary Key). |

FCURR |

text | Original currency (Primary Key). |

TCURR |

text | Destination currency of the exchange rate (Primary Key). |

GDATU |

date | Date on which the exchange rate is valid (Primary Key). |

UKURS |

text | The absolute exchange rate on the specific date. |

Filtering: KURST = var("exchange_rate_type").

Input table for Decimal Places in Currencies.

| Field | Type | Description |

|---|---|---|

CURRKEY |

text | Currency identifier (Primary Key). |

CURRDEC |

integer | Number of decimal places. |

Input table for Business Area Names data.

| Field | Type | Description |

|---|---|---|

GSBER |

text | Business Area (Primary Key). |

MANDT |

text | Client Identifier (Primary Key). |

SPRAS |

text | Language Key (Primary Key). |

GTEXT |

text | Business Area description. |

Filtering: SPRAS = var("language").

Input table for System status descriptions data.

| Field | Type | Description |

|---|---|---|

SPRAS |

text | Language Key (Primary Key). |

ISTAT |

text | System status (Primary Key). |

TXT04 |

text | Individual status of an object (short form). |

TXT30 |

text | Object status. |

Filtering: SPRAS = var("language").

Input table for Controlling area descriptions data.

| Field | Type | Description |

|---|---|---|

MANDT |

text | Client Identifier (Primary Key). |

KOKRS |

text | Controlling Area (Primary Key). |

BEZEI |

text | Name of the controlling area. |

Input table for Customizing time zones.

| Field | Type | Description |

|---|---|---|

CLIENT |

text | Client Identifier (Primary Key). |

FLAGACTIVE |

text | Indicates active records. |

TZONESYS |

text | Foreign key identifying the system time zone. |

TZONEDEF |

text | Foreign key identifying the default time zone for user. |

Filtering: FLAGACTIVE = 'X'.

Input table for Summer time rules.

| Field | Type | Description |

|---|---|---|

CLIENT |

text | Client Identifier (Primary Key). |

DSTRULE |

text | Daylight saving time rule (Primary Key). |

FLAGACTIVE |

text | Indicates active records. |

DSTDIFF |

text | Indicates the difference between daylight saving time and winter time. |

Filtering: FLAGACTIVE = 'X'.

Input table for Summer time rules (fixed annual dates).

| Field | Type | Description |

|---|---|---|

CLIENT |

text | Client Identifier (Primary Key). |

DSTRULE |

text | Daylight saving time rule (Primary Key). |

YEARACT |

integer | Valid for year (Primary Key). |

DATEFROM |

date | Starting date for the daylight saving time. |

TIMEFROM |

time | Starting time for the daylight saving time. |

DATETO |

date | Ending date for the daylight saving time. |

TIMETO |

time | Ending time for the daylight saving time. |

Input table for Summer time rules (variable dates).

| Field | Type | Description |

|---|---|---|

CLIENT |

text | Client Identifier (Primary Key). |

DSTRULE |

text | Daylight saving time rule (Primary Key). |

YEARFROM |

integer | Valid from year (Primary Key). |

MONTHFROM |

text | Starting month for the daylight saving time. |

WEEKDFROM |

text | Starting day of the week for the daylight saving time. |

WEEKDCFROM |

text | Starting weekday in month (occurrence number) for the daylight saving time. |

TIMEFROM |

time | Starting time for the daylight saving time. |

MONTHTO |

text | Ending month for the daylight saving time. |

WEEKDTO |

text | Ending day of the week for the daylight saving time. |

WEEKDCTO |

text | Ending weekday in month (occurrence number) for the daylight saving time. |

TIMETO |

time | Ending time for the daylight saving time. |

Input table for Time zone rules.

| Field | Type | Description |

|---|---|---|

CLIENT |

text | Client Identifier (Primary Key). |

ZONERULE |

text | Time zone rule (Primary Key). |

FLAGACTIVE |

text | Indicates active records. |

UTCDIFF |

text | Indicates the difference of time zone from UTC. |

UTCSIGN |

text | Indicates the sign of the difference from UTC. |

Filtering: FLAGACTIVE = 'X'.

Input table for Time zones.

| Field | Type | Description |

|---|---|---|

CLIENT |

text | Client Identifier (Primary Key). |

TZONE |

text | Time zone (Primary Key). |

FLAGACTIVE |

text | Indicates active records. |

ZONERULE |

text | Indicates the time zone rule. |

DSTRULE |

text | Indicates the daylight saving time rule. |

Filtering: FLAGACTIVE = 'X'.

Input table for User type data.

| Field | Type | Description |

|---|---|---|

MANDT |

text | Client Identifier (Primary Key). |

BNAME |

text | User key identifier (Primary Key). |

TZONE |

text | Time Zone. |

USTYP |

text | Classification of the user. |

Input table for User Name/Address Key Assignment data.

| Field | Type | Description |

|---|---|---|

MANDT |

text | Client Identifier (Primary Key). |

BNAME |

text | User key identifier (Primary Key). |

ADDRNUMBER |

text | Address Number of the Business. |

KOSTL |

text | User's cost center. |

PERSNUMBER |

text | Identifier of the person/user. |

The Activity configuration, Order status configuration, Production order category, User type seed files are provided as examples, and should be modified according to business requirements.

To set automated activities, the analyst should use the Activity configuration and User type seed files.

Activity configuration can also be used to translate activities and assign activity order.

Production Orders can go through multiple statuses at the same time, and some of them may not be useful for a clear analysis of the process.

The seed file Order status configuration is used to filter order statuses used in the transformations, break ties when more than one status is active (based on the standard process flow) and add the descriptions of the statuses.

Specific logics where created to select only one current status (the 'main' one) for each Production order, using the order predefined. Also, to select the listed statuses in the change-status models.

These logics are further explained in the Design Details section.

For your reference, all the Order_status_codes and their descriptions to populate this seed file can be found in the TJ02T (System status texts) SAP ECC table.

Note: Please consider not adding status code I0001 as it refers to the creation of either orders or operations. This activities are already being generated based on the transactional information, thus, adding this status will just duplicate them.

In SAP, the order category codes and their descriptions are customizable. Production order category is used to set the order categories desired to be present in the transformations.

For your reference, all the Order_category_codes and their descriptions to populate this seed file can be found in the DD07T (DD: Texts for Domain Fixed Values (Language-Dependent)) table. This is a big table so it is recommended to filter the table by 'Domain' = AUFTYP' and the Language value desired (e.g. 'E' for english) to bring only the Production order category values.

| Variable | Type | Description |

|---|---|---|

| date_format | string | Specifies the format variable for converting to date depending on the destination. |

| language | string | This variable specifies the system language, set accordingly to the default SAP system language. Default value is E (English). |

| exchange_rate_type | string | Defines the exchange rate to be applied on client currency in order to convert it into a single currency. Default value is M. |

| display_currency | string | This variable defines the currency to be displayed. Default value is USD. |

| use_operation_events | boolean | Determines if the Operation events are to be displayed or not. Default value is 'true'. |

| jcds_tracking_activated | boolean | When JCDS table tracking is activated and the variable is enabled, specific models for status-change activities will be created. Default value is 'true'. |

| production_deficit_percentage | integer | This variable is needed for setting up the 'Quantity deficit' tag. This should be populated as a percentage that represents the maximum admissible value of the ratio Goods_received_quantity / Order_item_quantity. (e.g. 5 would mean 5%). If there is no threshold for deficit, then set variable to zero (0). |

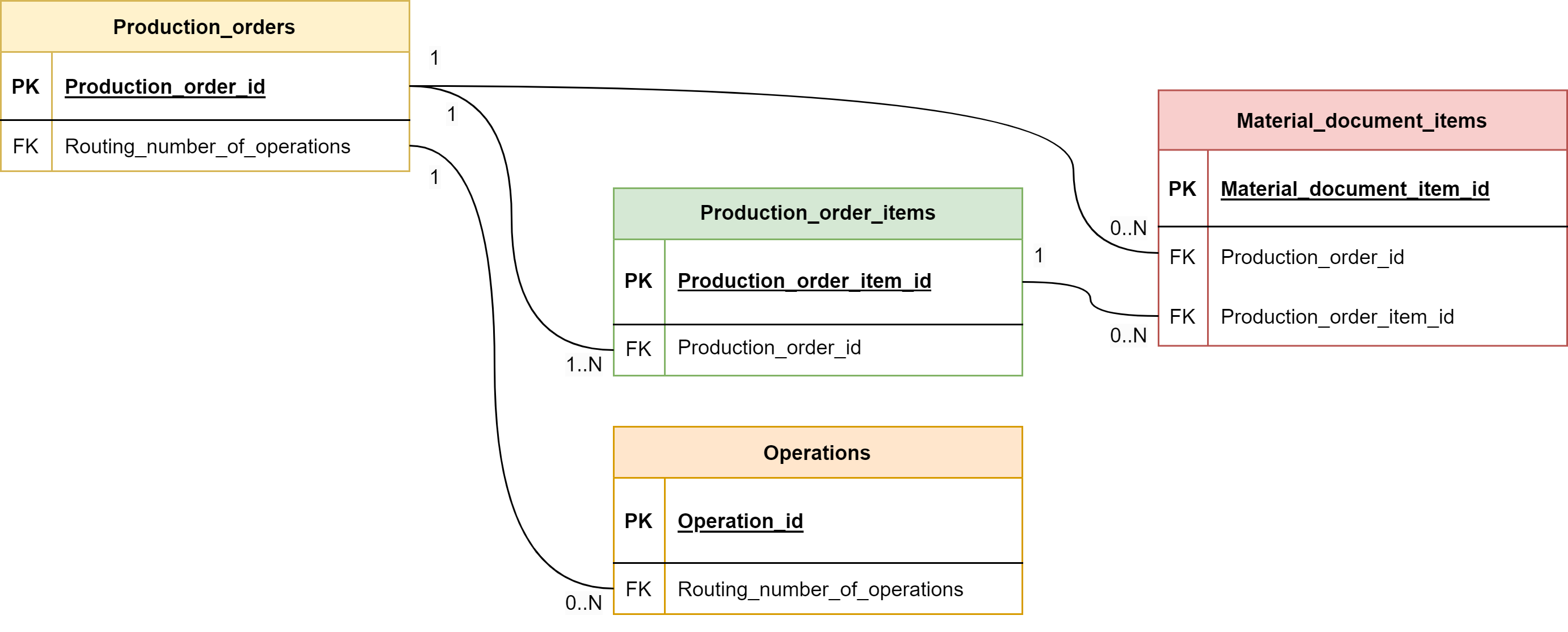

The following diagram shows all entities that are used for the process.

| Entity | Input Data |

|---|---|

| Material Document Items | MSEG |

| Operations | AFVC |

| Production order Items | AFPO, AUFK |

| Production orders | AFPO, AUFK |

| Activity | Entity | Description |

|---|---|---|

| Post goods issue | Material document items | Movement of consumption of raw material needed for the Production order. |

| Post goods receipt | Material document items | Movement of reception of finished product derived from the Production order. |

| Reverse goods receipt | Material document items | Reception reversal of finished products coming from the Production order. |

| Reverse goods issue | Material document items | Consumption reversal of raw material needed for the Production order. |

| Change operation description | Operations | A change in the description of an operation within the Production order. This activity will only be displayed if the variable 'use_operation_events' is set as 'true'. |

| Cancel operation confirmation | Operations | Cancel an operation previously confirmed. This activity will only be displayed if the variable 'use_operation_events' is set as 'true'. |

| Create partial operation confirmation | Operations | Partial confirmation done at operation level. |

| Create final operation confirmation | Operations | Final confirmation done at operation level. This activity will only be displayed if the variable 'use_operation_events' is set as 'true'. |

| Execute operation (Partial/Final) | Operations | This activity represents the time frame an operation took place. It contains Event_start and Event_end attributes. Basically, these fields are taken from the Confirmations (AFRU) table, where the actual execution times should be entered. This activity will be repeated as many times as confirmations are available in AFRU table. The name of the activity depends on the Final_indicator (AFRU."AUERU"). If the Final_indicator field classifies the confirmation record as a final confirmation, then the activity ni the model will be 'Execute operation (Final)', otherwise it will be named as 'Execute operation (Partial)'. This activity will only be displayed if the variable 'use_operation_events' is set as 'true'. |

| Execute all operations | Operations | This activity represents the time frame where all operations within a Production order took place. Basically, it looks (in AFRU table) for the first actual start execution date-time, which will be the Event_start, and the last actual finish execution date-time, which will be the Event_end, in all the operations of the same Production order. This activity will only be displayed if the variable 'use_operation_events' is set as 'false'. This activity summarizes all operations executions when the analyst does not want to have it broken down into each operation. |

Change operation status to value |

Operations | In the PP process, an operation can move across many statuses. Usually these statuses are related to the Production order status. This activity will only be displayed if the variable 'jcds_tracking_activated' is set as 'true' and the 'use_operation_events' is set as 'true'. |

| Change order description | Production orders | Changing the entered description of a production order. |

| Change total order quantity | Production orders | Change in the production order total target quantity. |

| Change order scheduling type | Production orders | Change in the type of scheduling set in the production order. |

| Change order basic finish date | Production orders | Change in the date the user estimates a production order will finish. |

| Change order basic start date | Production orders | Change in the date the user estimates a production order will start. |

| Change order basic start time | Production orders | Change in the time the user estimates a production order will start. |

| Change order basic finish time | Production orders | Change in the time the user estimates a production order will finish. |

| Change order total scrap quantity | Production orders | The scrap quantity entered in the Production order has increased/decreased. |

| Change order priority | Production orders | The priority entered in the Production order has increased/decreased. |

| Cancel production order confirmation | Production orders | Cancel a production order, that was previously confirmed. |

| Create partial production order confirmation | Production orders | Partial confirmation done at Production order level. |

| Create final production order confirmation | Production orders | Final confirmation done at Production order level. |

| Create production order | Production orders | Creation of a Production order at header level. |

| Execute production order (Partial/Final) | Production orders | This activity represents the time frame in which a Production order took place. It contains Event_start and Event_end. Basically, these fields are taken from the Confirmation (AFRU) table, where the actual execution times should be entered. If many confirmations exist, then many activities of execution will be generated, one for each confirmation record. The name of the activity depends on the Final_indicator (AFRU."AUERU"). If the Final_indicator field classifies the confirmation record as a final confirmation, then the activity ni the model will be 'Execute production order (Final)', otherwise it will be named as 'Execute production order (Partial)'. |

| Change production order status to Released | Production orders | The Release of a Production order. The release is a main step of the SAP ECC PP process. When the variable 'jcds_tracking_activated' is set to 'false', this activity is generated with a specific logic. Otherwise, when the variable is set to 'true' this activity will still be generated by JDCS related models. |

Change production order status to value |

Production orders | In the PP process, a Production order move across many statuses. This activity will track all the statuses for which the Production order went through. It will only be displayed if the variable 'jcds_tracking_activated' is set as 'true'. |

| Change storage location | Production order items | Change in the production order item total storage location. |

| Change indicator: order item not relevant for MRP | Production order items | MRP in SAP ECC PP means 'Material requirements planning'. When this field is flagged, it means the item is not relevant for planning requirements anymore. A new change in this field may affect the planned material requirements for the Production order. |

| Change stock type | Production order items | Change in what type of stock the production order item is. |

| Create production order item | Production order items | Creation of a Production order at item level. |

The app template follows 2 approaches for naming activities:

Approach 1: Activities that can be named based on transactional tables.

These activities have specific models where they were created and the name of the model derives from the activity name.

Example: Production_order_creation_events

Approach 2: Activities that can be named based on historical tables.

These activities have specific models and they are based on SAP ECC PP historical tables:

Approach 2.1: JCDS for status change events

All the activity names in the status change event models were created in the following way:

'Change' + [Entity_name] + ' status to ' + [Status_description]

Example: Change production order status to Released

In these models, the Order_status_configuration seed file is used to filter only the statuses desired to be tracked and their descriptions.

Approach 2.2: CDHDR and CDPOS for change log events

All the activity names in the change log event models were created in the following way:

'Change' + [Field_name]

Example: Change total order quantity

In these models, the Field_name comes from the selection of fields enabled to be tracked in CDHDR and CDPOS table.

Relevant considerations for both approaches:

To enable the creation of the models based on JCDS table, the variable 'jcds_tracking_activated' needs to be set to 'true' in advance.

If the variable is set as 'true', JCDS table needs to be enabled in SAP. Otherwise all models related to JCDS will produce no records. Also, for tracking change log events, CDHDR and CDPOS need to be properly set. Detailed instructions can be found in the section Instructions for enabling History Tracking in SAP ECC Production Planning.

Ìf neither of the aforementioned tables are activated in the Client, the transformations will still work properly.

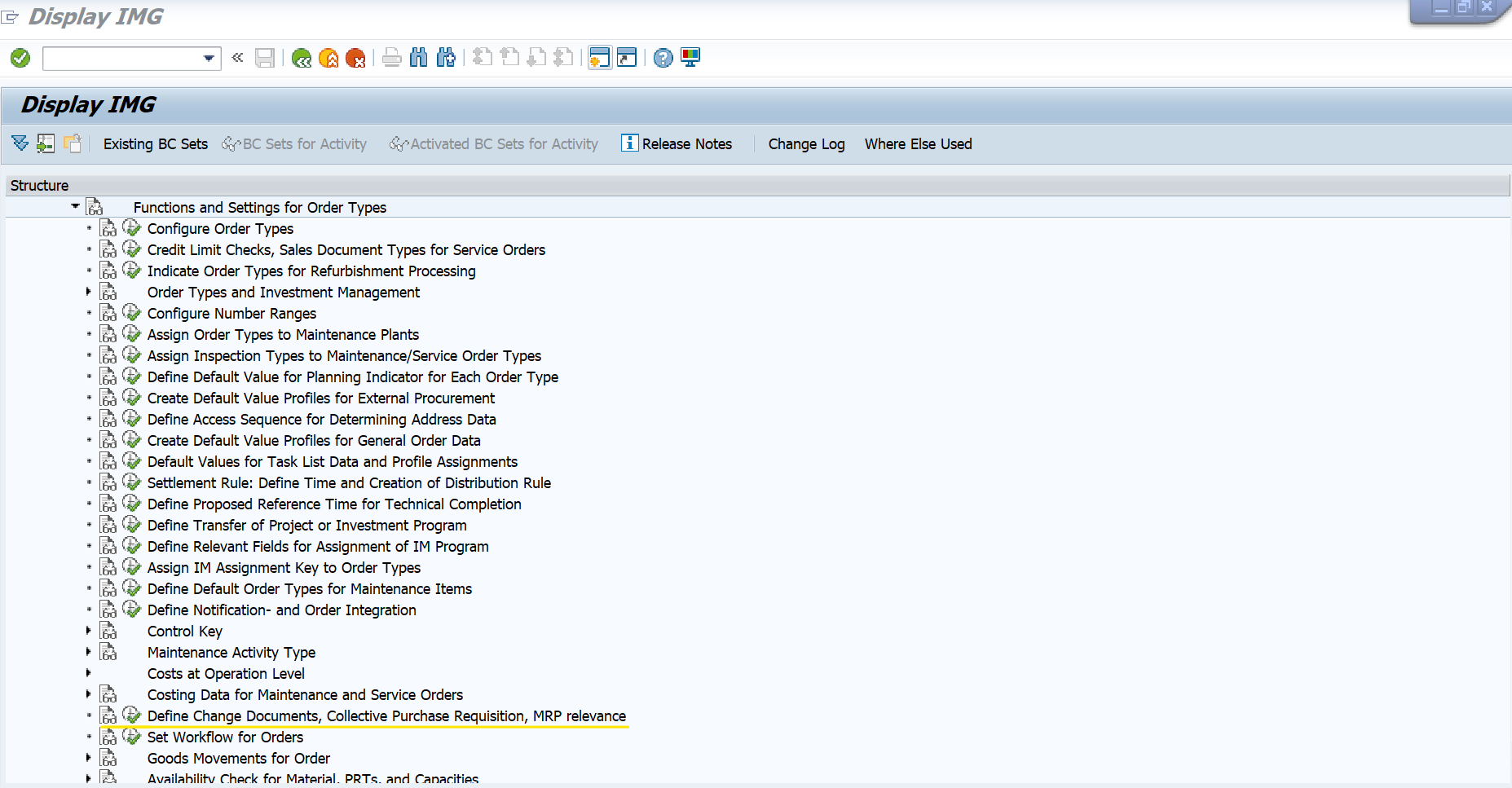

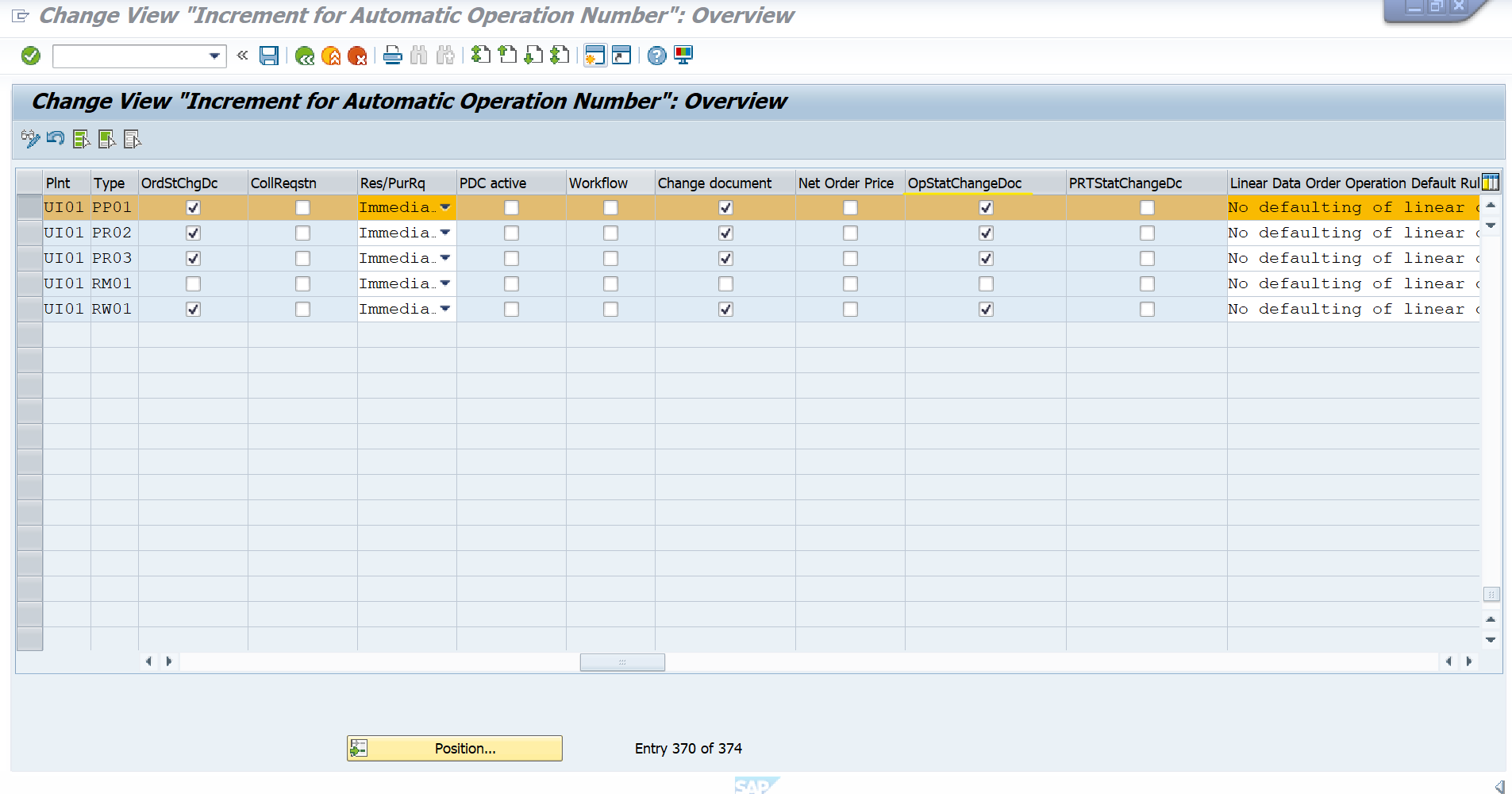

These instructions are intended to help analyst to enable the SAP ECC PP historical tracking of:

Instructions:

spro t-code and click on 'SAP Reference IMG' option.

These checks will enable JCDS (historical table of statuses) and CDPOS tables.

Save the changes and exit the transaction.

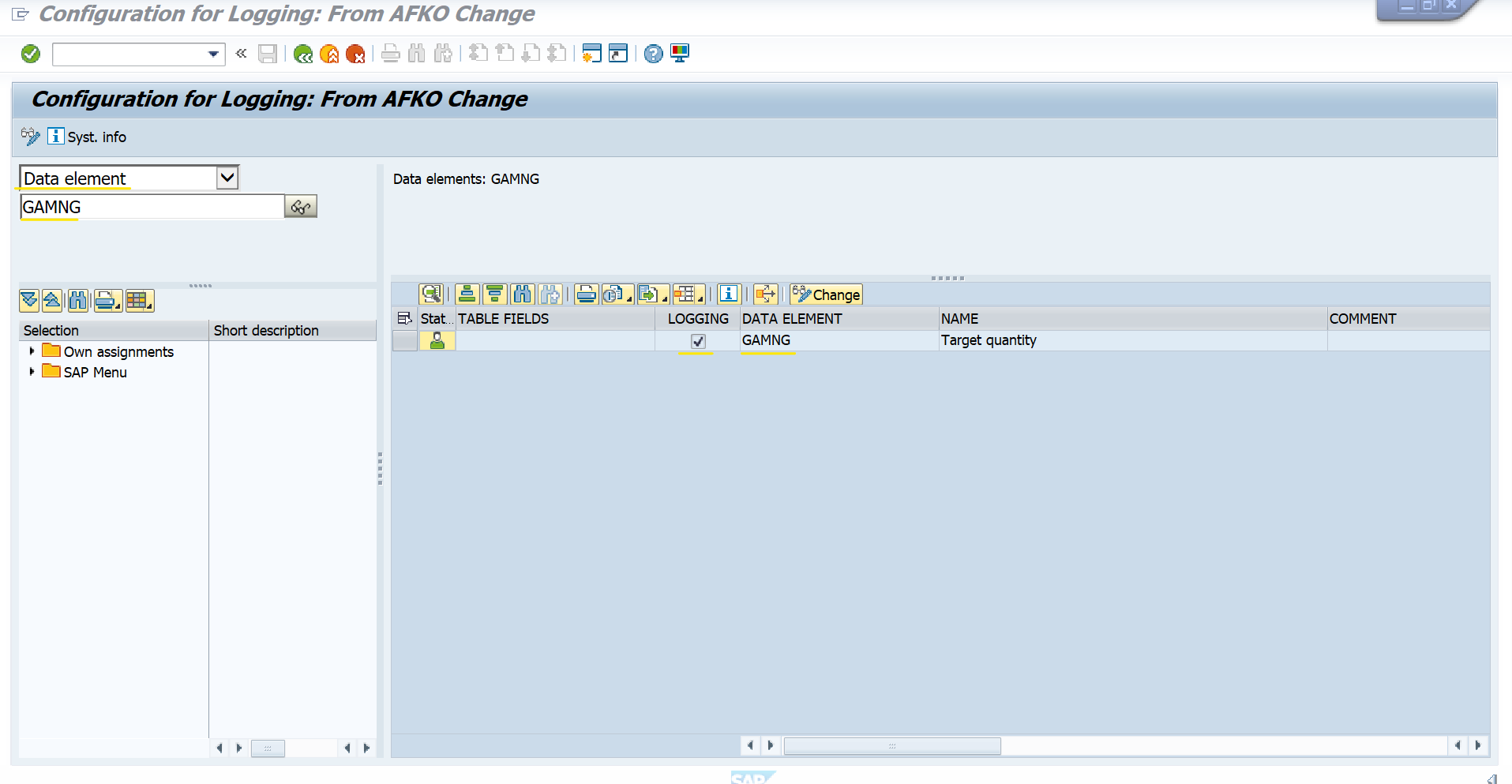

Go to the transaction aut01 and select the table needed to be tracked (e.g. AFKO table, GAMNG field) and check the 'Logging' option.

For this app template, the specific fields which need to be enabled in SAP are the following:

| Table | Fields |

|---|---|

| AUFK | KTEXT |

| AFKO | GAMNG, TERKZ, GLTRP, GSTRP, GLUZP, GSUZP, GASMG, APRIO |

| AFPO | PSMNG, PSAMG, LGORT, DNREL, INSMK |

| AFVC | LTXA1 |

Note regarding time zone conversions

In SAP ECC, there are specific date/time fields that are recorded in user’s time zone instead of server’s. These fields are being used for all activities related to execution events:

Specific logics in supporting models were created to convert these timestamps into server’s time zone to avoid discrepancies between timestamps of the activities (activities happening in an order that is impossible).

These logics adjust the following:

1. Time zone difference (in minutes) between each user and the SAP server

This logic works by calculating the UTC time for both, the user and server. After that, it brings the difference between both in minutes. Finally, this difference is applied to the corresponding SAP fields that are stored in the user’s timezone.

Example 1:

Consider the following scenario.

1. User1 is in Chile (GMT-4) and creates the order at 8:30:00 AM CH

2. The server is in Brazil (GMT-3), so the creation time is recorded as 9:30:00 AM BR

3. User1 enters the start_time for the execution of an order at 09:00:00 AM CH

4. The record is created without any changes as it is stored in user’s time zone (09:00:00 AM CH)

If the logic is not applied, then the activities would be order as follows:

1. Execute production order (9:00 AM CH)

2. Create production order (9:30 AM BR)

This cannot ever happen in a system as it is impossible to execute an order that was not created yet.

The supporting model will adjust the records to the server’s timezone, adding or subtracting the corresponding difference (in this case, it is needed to add 1 hour to the Execute event):

1. Create production order (9:30 AM BR)

2. Execute production order (10:00 AM BR)

2 & 3. Summertime rules applied to the user and to the server

These two summertime rule logics are also applied to consider those cases where the original time zone was modified in summertime.

They work as follows:

First, convert the record in user’s time to server’s (see bullet 1). Then, adjust the record with the user summertime rule, if applicable. Finally, adjust the record with the server summertime rule, if applicable.

Example 2:

Consider the following scenario.

1. User1 is in Chile (GMT-4) and summertime rule does not apply (then, still in GMT-4)

2. The server is in Brazil (GMT-3) and summertime rule applies (then, GMT-2)

3. User1 executes an operation at 8:30:00 AM chilean local time

The correct value for the execution time should be 10:30:00 AM, brazilian local time.

The conversion process will apply all 3 logics as follows:

1. For time zone conversion: the logic adds 60’ (GMT-4 vs GMT-3)

2. For summertime rule applied to the user, the logic subtracts 0’ (summertime rule is not active in Chile)

3. For summertime rule applied to the server, the logic adds 60’ (GMT-3 vs GMT-2)

As a result, the total addition is 120’.

Instructions for enabling History Tracking in SAP ECC Production Planning.